|

| May 21, 2013 | Volume 09 Issue 19 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Make nylon 3D-printed prototypes and parts in the office

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

Learn more.

Will it erode? 3D-printing materials comparison from Xometry

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

View Part 1.

View Part 2.

Graphene Handbook: Learn all about this wonder material

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Learn more.

Who knew? How colorants affect plastic

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

Read the full article.

Retaining magnets from JW Winco: Universal and clever

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

Learn more.

3D print tool steel with the ease of a plastic

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

Learn more.

Great Resources: Sheet metal design guide

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

Read the full article.

Particle foam perfectly distributed thanks to simulation with Ultrasim

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

Learn more.

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Read the full article.

CNC machining case study: One-of-a-kind computer chassis

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Read this Xometry case study.

Which parts should be 3D printed? AI combs through CAD files to find out

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

Read the full article.

9 key design tips for injection molding

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

View the video.

Metal additive manufacturing: Rocket turbopump design

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Read the full article.

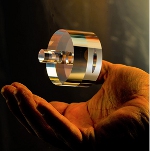

Transparent ceramics for extreme optics

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Learn more.

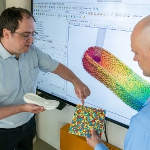

Softening steel problem expands computer model applications for Sandia researchers

Sandia National Laboratories researchers Lisa Deibler and Arthur Brown had a ready-made problem for their computer modeling work when they partnered with the National Nuclear Security Administration's Kansas City Plant to improve stainless steel tubing that was too hard to meet nuclear weapon requirements.

When steel is too hard it becomes brittle, so the plant ended up getting new tubing. However, Deibler said KCP needed a backup in case it couldn't find replacements in time to meet deadlines.

Sandia National Laboratories researcher Lisa Deibler holds a tubing specimen in a grip, ready to load it into the thermal-mechanical experimental system behind her. She and Arthur Brown at Sandia's California site worked together to develop a simulation for an annealing process to soften tubing that was too hard for the requirements of the job. [Photo: Randy Montoya]

Sandia's modeling, coupled with experiments, allowed the rapid design of an annealing process to soften the tubing while keeping the metal's desired structure. The model predicted how the microstructure would be affected by variations in the process, which improved researchers' confidence that the heat treatment would produce parts that met specifications.

Brown, a modeler at Sandia's Livermore, CA, site, said working on the model was a natural extension of a larger project, supported by Sandia's Nuclear Weapons program, called Predicting Performance Margins. Under that program, numerous Sandia researchers are studying the way microstructure affects properties of materials at various scales. Brown became involved in the project as a member of a team that developed a thermal-mechanical modeling tool to predict how microstructure and other properties change during forging. That led to his collaboration with Deibler and Joe Puskar, her Sandia technical adviser, on thermal profiles for welds.

When the need arose to address the tubing issue, Puskar contacted Brown to see if he could work with Deibler to help optimize a heat treatment, Brown said.

Experiments, modeling work together

Deibler, a postdoctoral appointee in Sandia's Materials Characterization and Performance Department in Albuquerque, provided experimental data that Brown fed into his model of stainless steel recrystallization. Recrystallization, in which grains in deformed microstructures are replaced by strain-free grains, occurs during annealing -- the process of heating metal to dissipate energy built up while the metal is compressed, twisted, or otherwise worked. Heat makes the metal softer and more ductile.

Deibler and Brown were able to solve the plant's real-life problem since recrystallization is part of the annealing process. And they were able to do it quickly because the model already existed.

Deibler's experiments indicated it was important to model two softening mechanisms: recovery and recrystallization. Recovery happens first within a microstructure when material is heated and softens. By measuring the hardness and the amount of recrystallization after each heat treatment, the team identified how much softening was due to recovery.

"It was important to model both softening mechanisms because we were seeing microstructures that contained no new recrystallized grains, but which had changed properties from the initial deformed material," Deibler said. "By failing to include the effects of recovery, our model couldn't predict why the properties weren't the same as the initial deformed material. Adding in recovery allowed us to account for the changed properties in microstructures with no recrystallization."

She described the work in a poster, "Design of a Heat Treatment to Soften Stainless Steel Tubing," presented at Sandia's winter 2012 Post-Doctoral Technical Showcase.

Heated furnace experiments form baseline

The team first developed a baseline for the model. Deibler performed heat experiments on the steel tubing since she didn't know the conditions under which it was manufactured. That effort required "a lot of shipping tubing around the country for various heat treatments," she recalled.

She put tubing samples in Sandia's thermal-mechanical experimental system at various temperatures for different lengths of time. Then she had the tubing sectioned, polished, and etched, and analyzed the images to see how much the microstructures had recrystallized. Brown fit her data with the model to simulate different heat treatments.

The simulation also required details about the furnace where the tubing would be softened. Heating a furnace quickly tends to overshoot the desired temperature, so the team used the model to determine whether it was better to heat the furnace quickly or slowly raise it to the correct temperature, Deibler said. Once Brown identified the optimal rate of increase and other factors, KCP technicians filled a furnace with tubing and measured temperatures at several locations inside. Brown then ran those profiles through the model, which allowed him to predict the impact of temperature variations on the tubing's final properties.

Forging, welding considered for computer model

The researchers want the model to handle both forging and welding because in some ways the two processes work against one another. Forging steel gives it a strong microstructure, but welding adds heat that can destroy those properties. "So if you were able to model that process, that would provide a lot more confidence in the overall modeling that their parts aren't going to fail," Deibler said.

In the future, the researchers want to use the model for all kinds of welding at Sandia: laser welding, resistance welding, and gas tungsten arc welding. Types of welding vary in their thermal rates -- how fast something is heated.

"Looking at how different heating and cooling rates affect the microstructure during welding would give us valuable information," Deibler said.

Sandia National Laboratories is a multiprogram laboratory operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy's National Nuclear Security Administration.

Source: Sandia

Published May 2013

Rate this article

View our terms of use and privacy policy